NextHood™: Selene's sustainable innovation confirmed by the new Life Cycle Assessment (LCA) study.

NextHood™: Selene's sustainable innovation confirmed by the new Life Cycle Assessment (LCA) study.

In the journey towards a more sustainable future, every choice matters. Selene understands this well and has decided to change the rules of the game by significantly reducing the environmental impact of its products. The revolution is called NextHood™, the new stretch hood that replaces the traditional 100% virgin polyethylene with a more sustainable formula containing 30% recycled polyethylene. A concrete choice, supported by a rigorous Life Cycle Assessment (LCA), demonstrating how innovation and sustainability can go hand in hand.

Why was a change necessary?

The packaging industry plays a crucial role in addressing environmental challenges. The traditional Power Stretch Hood, while highly effective, is made entirely from virgin materials. Recognizing this, Selene chose to change course by investing in research and development to find a solution with a lower environmental impact, while maintaining the same high quality. NextHood™ is the outcome of this vision.

How significant is this change?

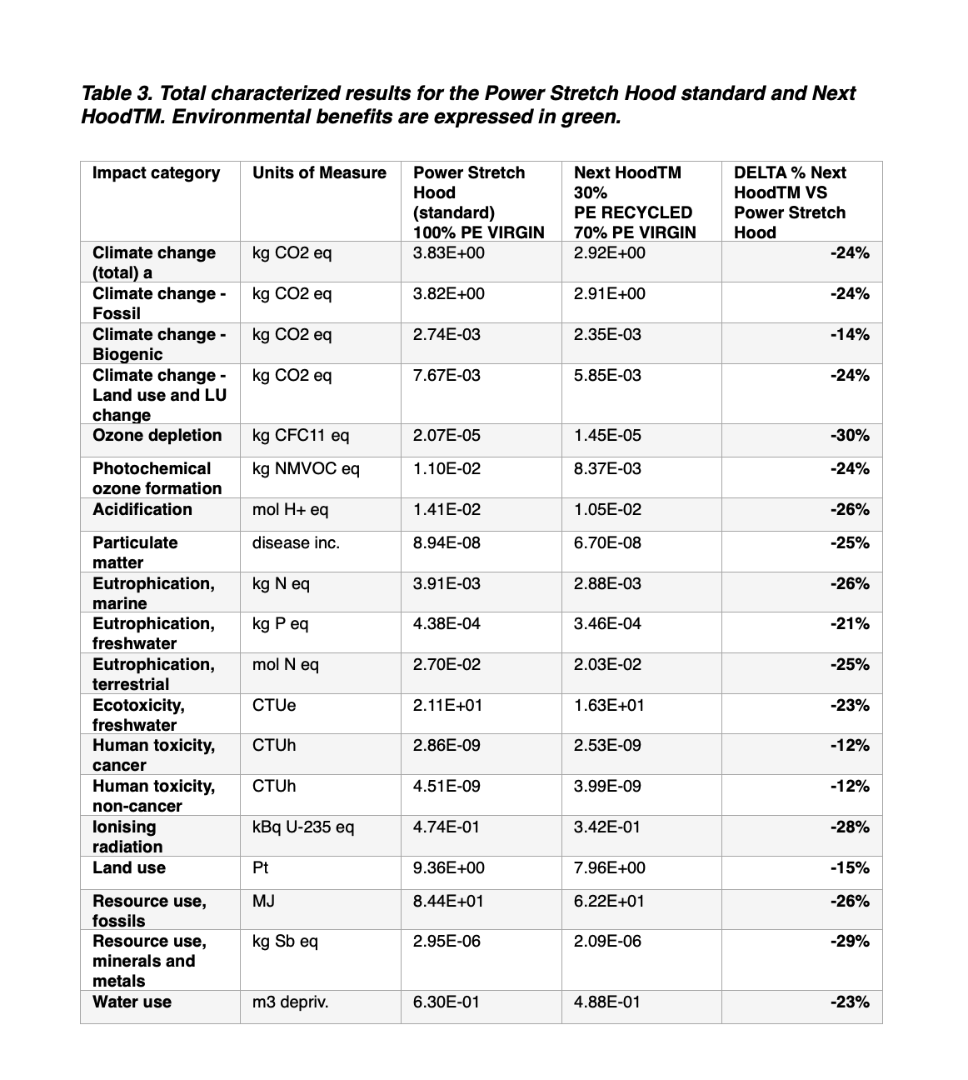

The LCA analysis clearly demonstrates the impact: transitioning from 100% virgin PE to 30% recycled material makes a substantial difference. The numbers speak for themselves. The LCA study, conducted according to the international standards ISO 14040 and ISO 14044, using the Ecoinvent v. 3.10 database, compared the environmental impact of the Power Stretch Hood and NextHood™.

The results are impressive:

- A 20% reduction on various impact categories related to four major areas: use of natural resources, human health, ecosystem effects, and the greenhouse effect.

- A 30% reduction in ozone layer depletion.

- A 24% reduction in carbon footprint, with a reduction in CO₂ emissions from 3.83 kg CO₂ eq to 2.92 kg CO₂ eq per 1 kg of product.

And that's not all. The use of recycled polyethylene reduces fossil resource consumption, lowering the environmental impact of production. A significant saving achieved without sacrificing the quality and reliability of the packaging.

How does NextHood™ work?

NextHood™ is a highly technical product: an elastic tubular film that fully wraps the pallet, protecting it during transport and handling. With the ability to produce in three or five layers, it ensures elasticity, tear resistance, and excellent stability. The real innovation lies in the material itself: Premium Recycled Polymer (PRP), a high-quality recycled polyethylene, made by processing selected plastic waste at the Capannori recycling facility. PRP is used as a secondary raw material in the production of NextHood™. This approach completes the cycle, creating a more circular production system and drastically reducing waste.

The impact analysis: what does it teach us?

The Life Cycle Assessment (LCA) identified the main environmental "hotspots," or critical areas that need attention:

- Raw material production: Virgin polyethylene and Ethyl Vinyl Acetate (EVA) are among the most impactful components due to their petrochemical origins.

- Additives used in compounds: The chemical formulation also affects the environmental balance.

Integrating 30% of recycled polyethylene (PRP) helps reduce environmental impacts, making NextHood™ a tangible step toward a more circular economy.

A commitment to the future

NextHood™ is not just a product; it's a statement of intent. Selene demonstrates that innovation and sustainability can coexist without compromise, offering its customers an intelligent and environmentally friendly alternative. This is just another step in a broader journey. Selene will continue to invest in solutions that enhance environmental performance, with the goal of continually reducing the environmental impact of the industrial packaging sector.